Emerging Technology Trends in Oil and Gas Operations

In today’s changing energy landscape, cutting-edge technologies can help oil and gas companies streamline operations, improve safety measures and enhance productivity. From real-time monitoring systems designed to reduce failure incidents to advanced drilling techniques, it is essential to not only consider the benefits innovative technologies can bring, but also the associated challenges and risks across your operations.

1. Technology designed to improve employee safety

Oil and gas workers face many potential dangers on the job. These include fires, falls, extreme conditions, machine hazards, chemical exposures and more. Fortunately, significant technological advances in the industry focus on helping to reduce these risks.

- Wearable devices — including smart watches, helmets, glasses and sensor-rich clothing — are a growing trend in the oil and gas sector. They can monitor worker health and movement, detect falls and warn of other conditions that could lead to accidents or injuries. Many wearables feature GPS tracking and SOS alerts, which can be lifesaving for lone workers in remote locations.

- Wearables may also be used for augmented and virtual reality applications (AR and VR). With AR, workers gain timely access to needed information, whether virtually or from remote experts in real-time. VR simulates real-world scenarios, helping trainees learn new skills in a safe, interactive virtual environment.

- Smart sensors set safety boundaries and warn workers when they are too close to active equipment or entering a restricted area. Gas sensors deployed throughout a workplace along with cloud-connected personal monitors can detect atmospheric risks and store data to inform preventive safety protocols.1

Potential risks of safety technologies

- Data breaches could occur when storing and transmitting sensitive data via wearable devices.

- Monitoring employee health and movement using wearables may raise privacy concerns.

- Integrating these technologies into existing systems and processes can be costly and complex.

- Sensors may trigger false alarms.

- Employee resistance or lack of training could hinder proper implementation and use.

Risk mitigation activities

- Prioritize robust cybersecurity measures to protect data.

- Clearly communicate the use and purpose of wearables and sensors with employees.

- Conduct hands-on training and regular inspections and create and maintain safety protocols for technology use.

- Establish contingency plans for technology failures and downtimes.

- Develop and communicate emergency response plans for situations when sensors issue critical warnings.

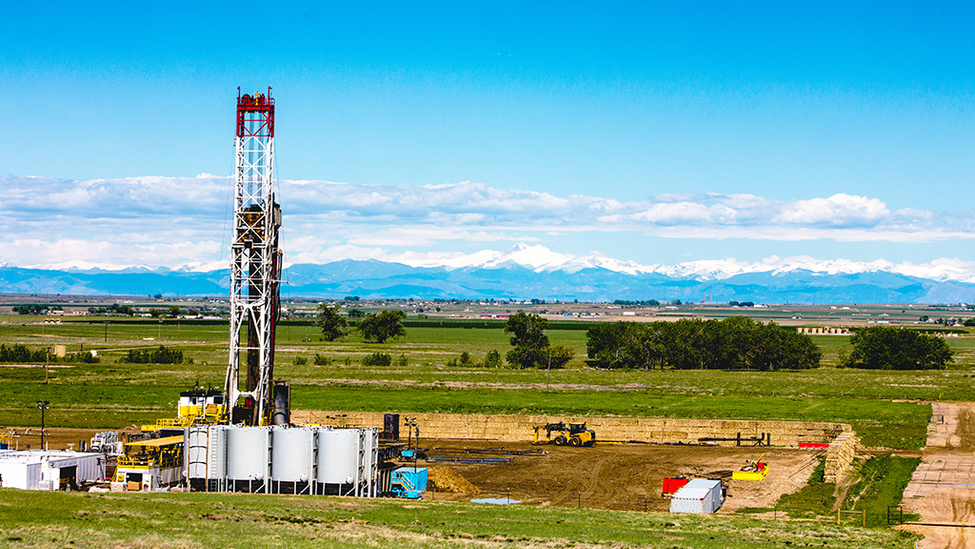

2. Technology for enhancing exploration and drilling

Advances in technologies for exploration and drilling are designed to help oil and gas companies safely reach new levels of production growth.

- Developments in seismic imaging and interpretation can transform oil and gas exploration efforts. New, ultra-sensitive equipment collects unprecedented amounts of seismic data across a potential drilling area, making 3D images of subsurface structures more precise. These images together with data analytics are useful to help companies identify drilling locations with greater accuracy and in significantly less time.2

- Measurement-while-drilling (MWD) provides real-time information to help steer a drill bit to its target. This technology consists of sensors and electronics installed in the drill string that measure various parameters — such as borehole pressure, temperature, vibration and torque — to inform the drilling process while it’s underway. Continuous improvement in the development of these sensors means surface transmissions are increasingly more accurate. High-speed data empowers operators to drill with even greater precision and accuracy with every improvement to the sensor technology.3

Potential risks of exploration and drilling technologies

- Drilling operations may encounter unexpected geological complexities, despite the use of precise technologies.

- Weather events, such as magnetic storms, can interfere in GPS systems.4

- Interpreting 3D models can be complex and require specialized expertise.

- Software bugs or failures could lead to incorrect drilling decisions.

- Environmental impacts from technology like seismic blasting can harm or disturb offshore wildlife.5

Risk mitigation activities

- Regularly update and maintain the data used in 3D models.

- Implement quality control procedures for data input.

- Ensure that employees responsible for interpreting 3D models are properly trained.

- Stay informed about relevant drilling and modeling regulations.

- Refer to the National Centers for Environmental Information High Definition Geomagnetic Model for more precise GPS navigation and establish back-up plans for potential technology disruptions.6

- When employing seismic blasts, be mindful of the physical effects of sound on land and sea creatures and follow protocols that reduce harm.

3. Advances in pipeline maintenance and inspection technology

With more than 2.6 million miles of pipelines moving natural gas and liquid petroleum each year, inspection and maintenance of these systems is an arduous and costly task.7 Advances in technology provide safer and more efficient alternatives to legacy methods.

- First developed for the military and aerospace industry, drones coupled with autonomous underwater vehicles are especially helpful in monitoring oil and gas facilities both onshore and offshore. Using high resolution cameras and thermal sensors, drones can relay detailed aerial images of large areas. The images may reveal variations in temperature, leaks and other risks. Among other advantages, this information helps inform plans to safely deploy employees to a site to conduct assessments and repairs. Commercial drone manufacturers are continuously improving and customizing applications that collect and report real-time data.8

- Intelligent pigging originated as mechanical cleaning systems for pipelines and has grown “smarter” over the past decade. Now, companies use GPS to deploy PIGs (pipeline integrity gauges). These gauges are fitted with probes and sensors to detect and measure corrosion, metal loss, cracks, dents, deformation and more. This is useful to enable workers to plan for and make repairs in a secure and intentional manner.9

- Using real-time data collected across multiple sources, pipeline integrity management systems help companies meet governmental compliance requirements and reduce pipeline incidents. These data analytics software tools help assess corrosion and simulate failure conditions, providing useful intel to inform strategies for mitigating additional risks.10

Potential risks of pipeline and maintenance technologies

- Drones may only detect above ground piping issues and have limitations in adverse weather conditions such as strong winds or heavy rain.

- Compliance with airspace regulations and obtaining drone operator licenses may be challenging.

- Equipment reliability may be compromised if technical failures or malfunctions occur.

- Pipeline access may be difficult, and interruption may be necessary with some types of intelligent PIGs.

Risk mitigation activities

- Contract with a reputable drone supplier and licensed pilot.

- Stay in compliance by consulting local, state and federal regulations.

- Routinely test GPS systems and establish contingency plans for technology failures and downtimes.

4. Prevention of well control Incidents

Investing in new technology is more important than ever as industry statistics suggest many well control incidents are attributable to crew fatigue, data-related mistakes and delayed action after detection of well abnormalities.

- For high-pressure reservoirs, blowout preventers — pressure safety valves and equipment — can be used to shut off machinery and stop well explosions before they happen. While many blowout preventers rely on hydraulics, new technology offers a hybrid approach, sometimes with NASA-developed propellants incorporated into these systems.11

- Real-time monitoring systems are a staple in drilling and have recently been applied to well control operations. With proper data analytics and enhanced monitoring systems, drilling crews get access to the information they need to make precise and proactive decisions aimed at minimizing well control risk.

Potential risks of well control technologies

- Blowout preventers can be greatly compromised by a single component failure.

- Copious amounts of data from monitoring systems can be a challenge to track and time-consuming to analyze.

- Mistakes in data analysis can occur if information is not accurate and comprehensive.

Risk mitigation activities

- Regularly inspect and account for environmental factors like weather and pressure that affect system parts.

- Audit monitoring systems to ensure metrics and datasets are reliable.

5. Technologies for equipment maintenance

Unplanned downtime due to equipment failures can take a financial toll on oil and gas companies. New data-driven maintenance strategies can help reduce breakdowns and their associated costs.

- Thanks to the Internet of Things (IoT), smart sensors can be installed on equipment to continually monitor and test various data points, such as temperature, humidity, pressure, vibration and corrosion rates.12 Advanced analytical software aggregates this data to provide real-time insights about equipment health, potential issues and lead times for service. Maintenance crews can use this predictive information to schedule repairs before breakdowns occur.

- Asset performance management systems (APM) are a suite of software tools for tracking and managing equipment reliability and availability. An effective system connects the many disparate equipment and machinery assets throughout the organization and uses advanced technology to monitor and measure their performance. Analytics can enable companies to improve key metrics such as uptime, mean time to repair, and asset longevity. IoT analytics can inform APM, enabling predictive and prescriptive maintenance.

Potential risks of equipment maintenance technologies

- Increased expertise is required for advanced technology.

- Internet-connected sensors and devices present cybersecurity concerns.

- Systems with dependence on software rely on consistent upgrades and compatibility.

- Pipeline locations are often remote and may lack reliable internet connections.

Risk mitigation activities

- Companies can look to high-tech industries for talent and additionally fill needs by upskilling or reskilling current employees.

- The National Institute of Standards and Technology offers cybersecurity suggestions to help stay protected.13

6. Real-time environmental monitoring

Oil and gas operations can have a range of impacts on the environment, from greenhouse gas emissions to oil spills and flares. Remote and real-time monitoring capabilities are helping companies protect the ecosystem from harmful pollutants.

- Advances in environmental monitoring include IoT-enabled sensors to measure air, soil and water quality. These devices can be deployed where pollutants are of concern. Key data is collected and analyzed continuously, allowing companies to detect and respond to potentially hazardous environmental exposures more rapidly.

- Carbon capture, utilization and storage (CCUS) is a groundbreaking technology that can help energy companies meet global energy and climate goals. CCUS captures carbon dioxide expelled from industry operations directly from the atmosphere and compresses it for use in a range of applications. Subject to strict regulations, it could be injected into depleted oil and gas reservoirs for permanent storage.14

- Optical gas imaging technology uses infrared cameras to visually detect gas leaks in real time. Advancements over the years have made this technology more affordable, portable and easier to use.15

Potential risks of environmental monitoring technologies

- CCUS technology and systems are expensive to develop and maintain.

- IoT sensors require internet bandwidth, high energy usage and data storage requirements.

Risk mitigation activities

- Tax incentives and government programs may incentivize CCUS implementation.16

- Establish or upgrade infrastructure to support new technology needs.

How Travelers can help oil and gas customers

Travelers offers oil and gas customers specialized insurance products and solutions, and innovative risk management services. With one of the largest dedicated underwriting, claim and risk control departments in the industry, our scale and specialized expertise in oil and gas, means we are able to deploy the right resources at the right time to meet customer needs.

Ask your insurance agent about Travelers insurance solutions for renewable energy operations.

Sources

1 https://www.energy.gov/...Natural%20Gas%20Benefits%20Report.pdf

2 https://primis.phmsa.dot.gov/comm/caex.htm

3 https://www.fhwa.dot.gov/innovation/everydaycounts/edcnews/

20220929.cfm

4 https://www.usgs.gov/communications-and-publishing/news/getting-down-earth-space-hazards

5 https://www.nrdc.org/bio/zanagee-artis/marine-life-casualties-offshore-drilling

6 https://www.ncei.noaa.gov/news/high-definition-geomagnetic-model

7 https://www.phmsa.dot.gov/faqs/general-pipeline-faqs.

8 https://www3.weforum.org/WEF_Drones_Ensuring.pdf

9 https://primis.phmsa.dot.gov/comm/factsheets/fssmartpig.htm

10 https://primis.phmsa.dot.gov/comm/Im.htm

11 https://spinoff.nasa.gov/Spinoff2020/ps_3.html

12 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7823190/

13 https://www.nist.gov/cyberframework

14 https://www.energy.gov/fecm/articles/carbon-capture-utilization-and-storage-rd-program-fact-sheet

15 https://www.epa.gov/sites/.../2018-08/documents/gd-52v.2.pdf

16 https://www.energy.gov/policy/articles/carbon-capture-utilization-and-storage-climate-change-economic-competitiveness-and