Developing a Winter Storm Plan for Your Business

Winter storms can bring a whole array of exposures to your buildings and operations. Some regions of the country have experienced record-breaking snowfalls in recent years, which can increase the potential for roof collapse.

Preparing for a winter storm

- First, you should know how much snow your building can safely handle. Be aware that building codes and design criteria based on building usage vary across the U.S. Contact a licensed structural engineer to help you determine the snow load design for your building, and if any improvements are needed to help prevent a future collapse. If it was built recently, this information may be available from your general contractor.

- Consider any weight that may have been added to the roof since its original design. This could include HVAC units, new roof coverings, solar panels or hanging equipment from the roof steel.

- Be aware of the potential for drifting snow, which could result from new additions with different roof heights or large roof-mounted signs.

- Inspect the roof and structure (inside and out) for any damage, such as cracks or corrosion.

- Inspect all roof drains and gutters to ensure they are clear of any debris. Ice accumulation along the eave can contribute to roof collapses.

- If your building has a wood bowstring truss roof, be aware that this type of roof is historically prone to failure, particularly due to truss deterioration where it meets the wall. A structural engineer should inspect these types of roofs on a periodic basis.

- If your building has a structural standing-seam metal roof and was built before the year 2000, a design weakness may be present.

- Pre-engineered metal buildings with structural standing-seam metal roofs can be particularly susceptible to collapse from excess snow loading.

- Studies and testing performed by the Metal Building Manufacturers Association (MBMA) and the American Iron and Steel Institute (AISI) in the mid-1990s found that existing metal roof system designs may not have fully accounted for the potential for structural failure under heavy loading conditions, such as drifting snow and ice or wind uplift1.

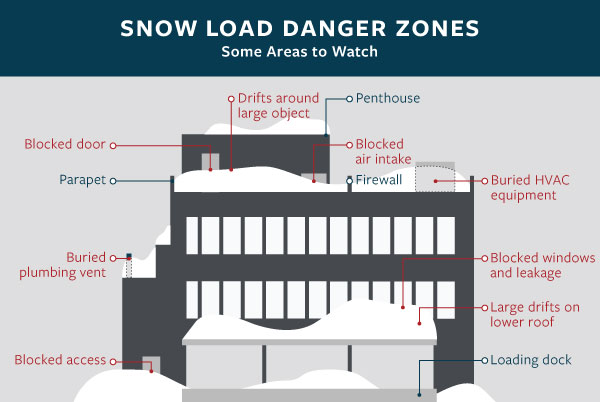

SNOW LOAD DANGER ZONES.

Some Areas to Watch:

- Drifts around large object

- Blocked Door.

- Parapet.

- Buried plumbing vent.

- Blocked access.

- Loading dock.

- Large drifts on lower roof.

- Blocked windows and leakage.

- Buried HVAC equipment.

- Firewall.

- Blocked air intake.

- Penthouse.

Develop a snow removal plan

- Start with a monitoring system to help you determine when to start snow removal. Establish action points so the snow load is not allowed to get so high that it becomes unsafe to get on the roof.

- Decide whether you will remove the snow or if you will hire a contractor to perform the work.

- If you decide to do the work yourself, you need to ensure you have appropriately trained individuals on hand to safely perform this work and the proper equipment to avoid damaging the roof covering.

- If you decide to have a contractor do the work, have them sign the contract early and make sure they can respond quickly to your call. Make sure the contract has appropriate risk transfer language and that the contractor has adequate insurance coverage to do this work. Your insurance agent or broker can help you determine what is adequate for your exposure.

- A structural engineer and roofing contractor should review your snow removal plan to help ensure that it does not increase the danger of collapse or cause damage to the roof covering, and is conducted in a manner that is safe for those working on the roof. For example:

- Use of equipment such as large snow blowers on an already heavily snow-loaded roof may present an excessive load.

- Snow removal should be done in a manner that keeps the roof load as symmetrical as possible.

- Metal shovels or ice chippers could damage the roof covering and allow leakage, wetting of insulation and damage to building contents.

Develop a contingency plan

- Prepare for the worst. Develop plans to help protect your building and equipment, including business continuity plans.

- Clearly identify shut-off valves for utilities, such as gas, water and electricity.

- If the building is protected by automatic sprinkler systems and the system needs to be turned off and drained, due to the potential for imminent roof collapse, it is important to eliminate all possible sources of ignition. Possible sources of ignition could include, but are not limited to: smoking, heating equipment, electric lighting and power systems, and maintenance activities involving cutting, welding, grinding or similar hot work. Contact the fire department and your property insurance company.

- After the plan has been implemented, evaluate its effectiveness and make any necessary changes.

Source

1 American Iron and Steel Institute Research Report RP01-8 “Axial Strength of Purlins Attached to Standing Seam Roof Panels”