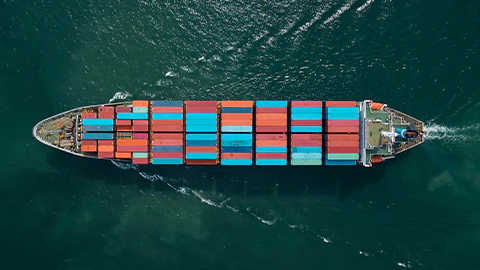

Protecting Your Cargo in Transit

When intermodal, or containerized, cargo arrives at its destination damaged, it can lead to long delays in coordinating replacement goods, potentially disrupting your supply chain and threatening relationships with key customers. Taking steps to ensure that your cargo is properly protected can help prevent costly business interruptions.

Physical damage and wetting damage account for over 56% of Travelers’ ocean cargo claims.1 Intermodal containers and the cargo they protect are routinely subjected to heavy rolling, pitching and vibration, as well as exposure to severe weather conditions, while in transit. The shipper is responsible for ensuring that the cargo loaded within is properly secured against these expected circumstances.

It is common for shippers of intermodal cargo to rely on third-party logistics companies to properly load and secure their cargo. It is critical for shippers to verify that the third parties they hire have the right experience to properly protect their product for the conditions it will face during shipment.

Properly securing containerized cargo from shifting damage requires training and experience and generally must follow international maritime requirements. Wetting damage of containerized cargo can result from external sources, such as rain and seawater spray entering a damaged container, as well as atmospheric moisture (referred to as “sweat”) trapped within the container after the doors are closed. Therefore, it is important for both shipper and their third-party agents responsible for loading containers to be knowledgeable in the proper methods to identify and control these exposures.

Inspecting and securing cargo considerations

Before loading begins, containers should be thoroughly inspected. This includes examining for holes or damage to the container’s steel structure. Shippers should also closely examine the mechanical door-closing devices as well as the rubber door gaskets. Further consideration should be given to the following:

- Is the cargo vulnerable to cargo sweat? If so,

- Are container vents properly set?

- Should moisture-absorbing materials be placed within the container?

- Are moisture barriers necessary?

- Is the cargo properly secured?

- Are void spaces filled to prevent sliding?

- Have adequate lashings and bracing material been properly installed to secure the cargo without damaging it?

- Is the cargo susceptible to damage from high or low temperatures?

- Should a refrigerated container be used?

- Should additional temperature sensors be inserted with the cargo for retrieval upon arrival, to be certain conditions are as expected during the course of shipment?

“Shippers who rely upon third parties to properly load and secure their products may also want to consider working with local marine surveyors to help supervise the loading of containers, especially if there is any doubt as to their experience with the type of product being shipped,” said Kirk Rider, Director of Ocean Marine Risk Control at Travelers. “While this can be an added expense, it may also be the best way to help ensure that proper methods and procedures are followed when shipping cargo by intermodal containers.”

Selecting the right warehousing/storage for your cargo

Warehousing and storage risks can happen at any point along your cargo’s journey, including while goods are in port awaiting shipment. Risks include improper stowage, fire, theft, water damage and contamination.

You may want to consider your risk tolerance for warehousing and storage when choosing a warehousing partner. Your selection should take into account your cargo’s exposure to loss. For example, theft-prone commodities will need extra consideration in regard to security. Perishable commodities will need specific refrigeration solutions.

Warehousing considerations, however, can be important for all types of commodities. Even if the items themselves are not of a high value, they may play a key role in a manufacturing process, and any damage at a storage location may lead to costly delays. It is important to recognize related importance of the cargo, even in the absence of intrinsic value or potential for spoilage.

To vet warehousing partners, look for companies that participate in relevant industry associations, regularly collaborate with law enforcement agencies and demonstrate expertise relevant to your warehoused products whether they are susceptible to handling damage, theft or both.

Cargo insurance

No matter how well shipments are packed and prepared for transit, damage can still occur. Obtaining adequate ocean cargo insurance coverage is key, as even experts in moving cargo can be surprised by responsibilities they didn’t know they had. When a supplier or freight forwarder handles the overseas cargo insurance on your behalf, there may be uncertainty about coverage provided.

- Is the supplier’s insurance coverage “all risk” or something less?

- If there is a question or problem, will you have access to the insurance carrier directly?

- What is the claim-filing process? Do the carrier’s Claim professionals have the resources to efficiently resolve your claim?

Receiving cargo

When cargo arrives at your facility, carefully inspect the intermodal container as well as the product as it is being unloaded, and document any conditions of damage or wetting that you notice. Upon arrival, check the container for signs of recent damage, holes and freshly dented areas, as these are indications that cargo inside could be adversely affected. If your cargo is susceptible to breakage, it can be helpful to open and examine several packages at various stages during the course of unloading from the container.

If cargo damage is found, the following checklist can help document any losses:

- Stop unloading operations. Photograph the damage conditions while the cargo still remains within the container.

- Preserve evidence:

- Photograph the closed door panels of the intermodal container, capturing the container’s identifying descriptions.

- Compile photographs of the container’s internal and external side walls, the container roof and decking, whether showing obvious damage or not.

- Use chalk or some form of temporary identifier to highlight areas where it appears the container has been damaged and take photographs from various angles and distances. Include a ruler or some other reference that will help demonstrate size and distance of the damage.

- If wetting damage is observed, photograph the condition of the wet damaged product within the container and after discharge.

- Carefully examine the container for possible points of external water ingress.

- Photograph the vents and determine whether or not they were open or closed upon arrival.

- Photograph all door seals and locking devices.

- Collect samples of any standing water or other suspected source of the wetting. Preserve it within a clean container.

Preserve samples of wetted product as well as packaging and place it within a new, sealable (zip-lock) plastic bag for potential analysis at a future date by claim professionals. After unloading the product, try to separate the shipment, both sound and damaged product, from other product within the warehouse for future examination by loss adjusters. It is also important to make notations on any delivery receipts or other shipping documents provided by the delivering carrier. Note the extent of damage, including the number of items/boxes as well as a short description of the nature of the damage, such as wetted, crushed, torn, etc.

Damaged cargo can be costly to your business. Taking steps to help protect your cargo, such as knowing the right questions to ask third-party logistics companies and working with a surveyor to help ensure that cargo is properly loaded, can help protect against damage to your cargo and potential business interruptions.

Source

1 Travelers claim reporting, 2022-2024.