Using Temporary Heaters on Construction Sites

Whether for employee comfort, preventing frozen water pipes or to maintain temperatures necessary for materials to set (such as adhesives), the cold weather season is a time when temporary heating systems on construction sites are in high demand. If temporary heaters are not operated correctly, they can pose a significant threat of fire to a project, not to mention potential harm to employees.

Every year, construction site fires occur due to improper selection, setup, use and management of temporary heaters. Construction fires can lead to significant or total loss. Fire risks increase as well when temporary heaters, even those properly selected and set up, are left running continuously or left unattended.

Given the hazards temporary heaters can present, it is important to select the right heater and include their use and precautions within your site-specific safety plan to help ensure heaters are used safely.

Choosing the safest type and best practices for using temporary heating

The permanent heating system, once installed and functional with all safety controls in place and operational, is the best source of heat during construction. If this is not an option, the following temporary heating devices are available:

Indirect fired

Indirect fired heaters are commonly fueled by diesel, propane or natural gas. The flame is contained in a burn chamber, where cool air passes over and around a heat exchanger and warm air is ducted into the building. The higher cost and lower efficiency of these heaters are offset by the lower risks associated with general use, as well as the lower potential for introducing carbon monoxide into enclosed buildings.

Tips for using indirect fired heaters safely include, but are not limited to:

- Units should be located on stable ground outside the building.

- For gas-fired units, all fuel line piping should be flexible, American Gas Association (AGA) rated, and secured against physical damage.

- Fuel tanks should be secured and protected with bollards or jersey barricades.

- Flue stacks should be located away from combustibles and located to prevent fumes from entering the structure/building.

- Units, including all hoses and fuel tanks, should be inspected and maintained regularly by a qualified vendor/service company through a written agreement.

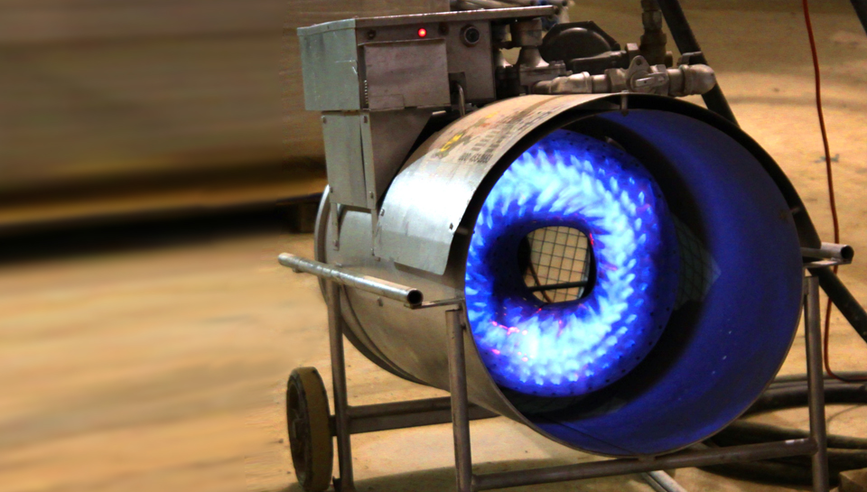

Direct fired

Direct fired heaters, often referred to as “salamanders” or “torpedoes,” convert 100% of the fuel being used into heat. They have relatively low operating costs, are easy to transport and locate, and are a powerful heat source. The inherent hazard is that the unit provides a direct flame, which, if too close to combustibles, can lead to a fire. It is generally not recommended to use a direct fired heater inside a wood frame structure. Due in part to maneuverability, these smaller units may also be more prone to tipping over. There is also an increased potential for dangerous levels of carbon monoxide inside the building that can create a serious health hazard for employees.

Tips for using direct fired heaters safely include, but are not limited to:

- Place heaters on a non-combustible surface that extends four feet in front of the unit, unless approved otherwise by the manufacturer.

- Be sure units are mechanically secured to prevent movement.

- Ensure electronic flame sensors or pilot safety valves are in place.

- Verify the unit is shut off and has cooled down before refueling. Never refuel indoors or within 50 feet of the building.

- Maintain proper safety clearances on all sides from combustible materials.

- Carbon monoxide detection, alarms and make-up air systems should be used.

Electric

Portable electric heaters may meet the needs for temporarily heating smaller areas. These heaters use a filament or ceramic disc to create heat, and a fan disperses the warm air. Advantages include a reduced risk of health and safety exposures to employees, and disadvantages include a need for electrical power, and perhaps the need for multiple heating units.

Tips for using electric heaters safely include, but are not limited to:

- Units should only be used in a dry environment.

- Ensure the electrical circuit is rated for the size of the unit.

- Utilize ground fault protection for employee safety.

- Protect electric heaters from potential tip over.

- Locate heaters away from combustible materials.

All temporary heaters should be UL, CSA or ETL listed and provided with automatic high temperature, tip over and safety shutdown capabilities. As part of a general contractor’s approach to managing subcontractors, prior approval should be required to allow heaters on-site. Also, management should ensure that portable heaters are shut off and secured in the off position when left unattended. If it is necessary to leave a heater on, such as during non-working hours, security or other personnel should perform frequent inspections. It is also recommended that the local fire department be informed when any type of temporary heating is being operated after work hours.