Supply Chain Technologies and How to Address Hidden Risks

On a global scale, supply chain disruptions are happening with greater frequency. Accelerating the adoption of innovative technologies across an entire supply chain may help drive efficiencies and speed. However, fast adoption may also introduce unforeseen risks

(DESCRIPTION)

Travelers Logo. Title: Transforming Today’s Global Supply Chains

(SPEECH)

[MUSIC PLAYING]

Supply chain disruptions continue to impact today’s technology companies.

(DESCRIPTION)

Images depicting different channels of supply chains begin to appear on screen.

(SPEECH)

Global shortages of critical materials and components have exposed supply chain weaknesses and accelerated the adoption of advanced technologies, such as additive manufacturing, automated facilities, drones and digitization.

(DESCRIPTION)

Robots move materials through a warehouse.

(SPEECH)

These solutions can transform supply chain management, reducing inefficiencies and increasing speed to market. Successfully integrating them into your operations requires a plan to address potential risks.

If you are turning to additive manufacturing to create products faster, consider developing a robust product testing program to minimize product defects.

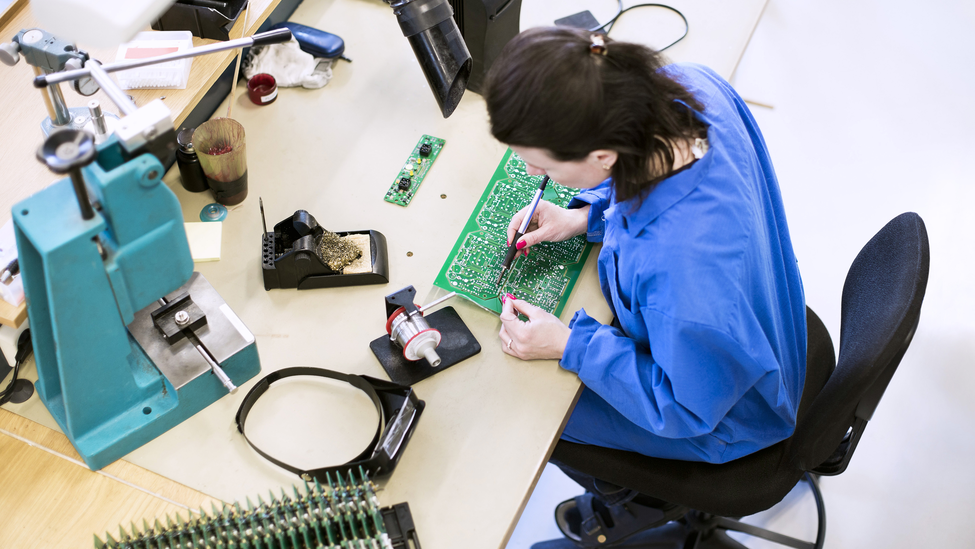

(DESCRIPTION)

Individuals test a product; a 3D printer creates a component.

(SPEECH)

Automated facilities, drones and tracking devices call for implementing proper safety protocols designed to reduce risks.

(DESCRIPTION)

Robotic tracking devices move around on a warehouse floor, workers in PPE monitor machines in a manufacturing facility.

(SPEECH)

Real-time, end-to-end visibility requires digitizing your supply chain ecosystem and incorporating the necessary IT security measures to protect the data generated across your interconnected global networks.

(DESCRIPTION)

Individuals at various computer stations, an image of a globe with lines connecting countries.

(SPEECH)

As you grow your global operations, you may find yourself vulnerable to supply chain disruptions. Including insurance is an important asset in managing risk.

Ask your agent or a Travelers representative about Travelers’ Global Companion℠ Plus+ policy for global coverage solutions and more.

(DESCRIPTION)

Learn more ways to cover your global risks.

Visit travelers.com/global

[MUSIC PLAYING]

(DESCRIPTION)

Travelers Logo. It’s better under the umbrella®.

Some footage was filmed before the Covid-19 pandemic.

Fortifying supply chains

Some supply chain disruptions come in the form of global shortages of critical materials and components. These disruptions can make it challenging to effectively operate your business and meet customer expectations. Advanced technologies like additive manufacturing, automated facilities, drones and digitization may provide solutions to help fortify your supply chains. However, these solutions may introduce new vulnerabilities. Let’s look into some of the hidden risks these innovative supply chain technology solutions may present.

Additive manufacturing

Additive manufacturing (AM) is a manufacturing process of adding material, layer by layer, to make a product. Sometimes referred to as digital printing, AM is innovating manufacturing in many areas. It uses data, computer-aided design software and 3D object scanners, which brings digital flexibility and efficiency to manufacturing. Applied effectively, AM delivers simplification, performance and precision.1

With the ability to produce components in-house rather than relying solely on imports, companies can leverage AM to increase production speed, shorten production cycles, allow for easier product customization and more. But, there are risks. AM is a relatively new means of production. Robust material and product testing are needed to help verify that parts meet design requirements.2 Errors such as loading the wrong material into a 3D printer could also affect part consistency and quality.3 At each step in a digitized production process, the data generated is vulnerable to cyber risks, including potential threats involving intellectual property. Putting measures in place like conducting regular risk assessments and adopting a comprehensive cyber risk strategy can help address these exposures.

Facility automation

Robotics and artificial intelligence (AI) provide opportunities to help improve efficiency and reduce waste in manufacturing. They can also make customization a more affordable option and allow facilities to be located closer to end consumers, reducing shipping costs and delays. Automated manufacturing can also produce real-time data on-site to inform production decisions.4

Similarly, deployment of drones and autonomous robots in manufacturing and supply chain operations is expected to increase. These technologies enable efficiencies, including saving time on inventory checks, streamlining mobility across sites, enhancing asset monitoring and increasing compliance. Drones, typically thought of in open spaces, are also being used within larger manufacturing or warehousing structures to record compliance data, conduct inspections without shutting down production lines, reach asset locations quickly and transport items around the plant with greater efficiency.5

Automated facilities, drones and autonomous robots can transform manufacturing and bring efficiencies to supply chains. However, they also come with limitations. Like all machines, robots can malfunction and may need to be serviced or reprogrammed.6 Because skilled technicians such as robotics engineers can be scarce and expensive to retain, it’s important to secure the right external partner or in-house talent to optimize and maintain these new technologies.

Digitization

Moving from paper drawings and specs to document-sharing software and computer-aided design (CAD) files can help improve efficiencies within the manufacturing process and throughout the entire supply chain. It can speed up the process the same way converting mail to email does, ultimately saving money. A digitized process allows for constant data collection and decisions based on real information. It also provides capabilities that seamlessly tie in and consolidate real-time data from multiple locations on one dashboard.7

While digitizing your supply chain ecosystem may improve data collection and foster better decision-making through end-to-end visibility in real-time, it also has the potential to open your data to more eyes than just yours. Manage that risk by incorporating the necessary IT security measures, including cyber risk insurance, which could play a role in helping to protect the continuous stream of data generated across your interconnected global supply chain networks.8

Mitigating risk in the global economy

Global insurance coverage is a valuable tool in managing risk that comes with implementing technological advancements into your global supply chain operations. And, today’s global marketplace means that you need to be covered wherever you develop, make, distribute or sell products. Learn how Travelers Global CompanionSM Plus+ can help protect you, your employees and your business.